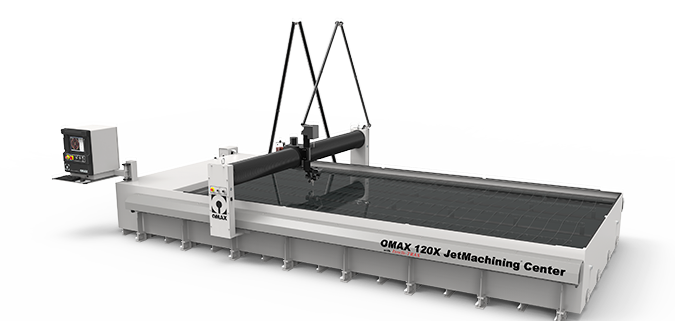

Machine Description

The OMAX 120X JetMachining Center Series is one of the largest OMAX bridge-style machines. The OMAX 120X features the high precision Intelli-TRAX® linear drive technology designed exclusively for the abrasive waterjet environment. This robust and reliable system maximizes production and profitability. The large cutting area of the 120X makes it ideal for multiple part projects or large-scale part production.

- Multiple table sizes available

- Rapid water level control for submerged cutting

- A work envelope offering an X-Y cutting travel from 13’4″ to 40’0″ x 10’0″ (4,064-14,224 mm x 3,048 mm)

OMAX 120X/S JetMachining Center

The 120X/S has an X-Y cutting travel of 13’4″ x 10’0″ (4,064 mm x 3,048 mm)

Footprint (with controller) 21″8 x 17’3″ (6,604 mm x 5,258 mm)

OMAX 120X JetMachining Center

The 120X has an X-Y cutting travel of 20’0″ x 10’0″ (6,096 mm x 3,048 mm)

Footprint (with controller) 28’4″ x 17’3″ (8,636 mm x 5,258 mm)

OMAX 120X-1 JetMachining Center

The 120X-1 has an X-Y cutting travel of 26’8″ x 10’0″ (8,128 mm x 3,048 mm)

Footprint (with controller) 35’0″ x 19’2″ (10,668 mm x 5,842 mm)

OMAX 120X-2 JetMachining Center

The 120X-2 has an X-Y cutting travel of 33’4″ x 10’0″ (10,160 mm x 3,048 mm)

Footprint (with controller) 41’8″ x 19’2″ (12,700 mm x 5,842 mm)

OMAX 120X-3 JetMachining Center

The 120X-3 has an X-Y cutting travel of 40’0″ x 10’0″ (12,192 mm x 3,048 mm)

Footprint (with controller) 48’9″ x 19’2″ (14,859 mm x 5,842 mm)

Optional Accessories

- A-Jet

- Rotary Axis

- Tilt-A-Jet

- Terrain Follower/A-Jet

- Collision Sensing Terrain Follower

- Precision Optical Locator (POL)

- Bulk Abrasive Delivery System

- Variable Speed Solids Removal System (VS-SRS)

- Laminar Filter

- Laser Feature Finder

- Z-Axis Pneumatic Drill

- Water-only MAXJET 5 Nozzle

- OMAX Mini MAXJET 5i Nozzle

- 7/15 Mini MAXJET5 Nozzle

- Manual Tilt Z-Axis

- Water Recycling System

- Reverse Osmosis System

- Material Holding Kit

- DualBRIDGE

- DualPUMP Package